our Our commitments

(CSR Report 2022)

CREATE

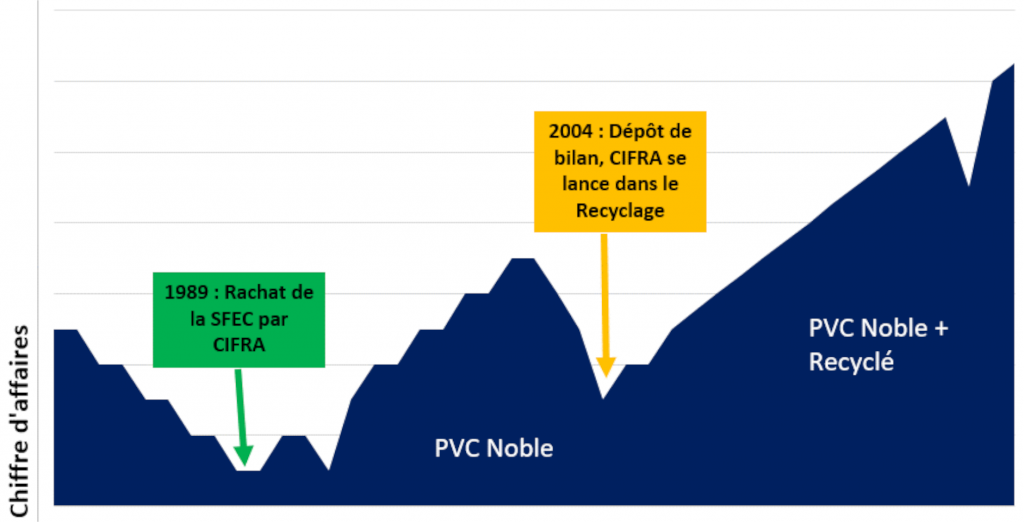

1 – History

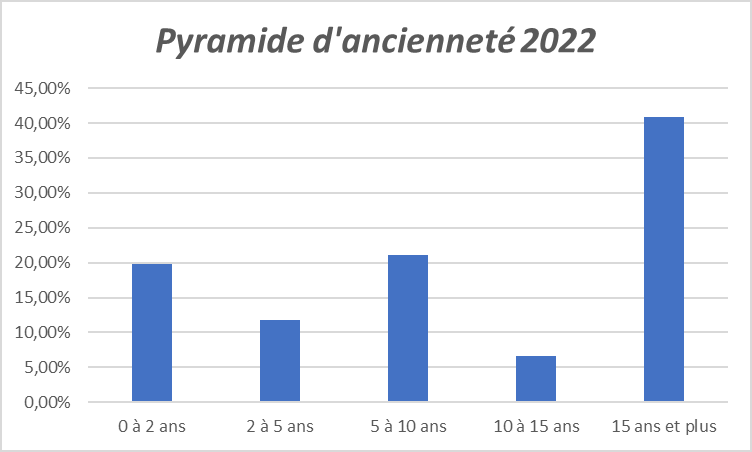

Employee allocations

In 1989, the SFEC company, after filing for bankruptcy, was taken over and renamed CIFRA for Calandrage Industriel Français. Following this event, the first site was sold and the activity was refocused on the second factory, called “La Plaine”, to which was added a third site, called “Eiffel”. The head office, the production site with the three calenders and the sales department were grouped together in the “La Plaine” building, while the “Eiffel” building has housed the testing and development laboratory, the printing department and a large storage area since 1992. In 2002, a new raw material storage building was added next to the “Eiffel” building. It was then common to separate the two buildings under the names “Eiffel 1” and “Eiffel 2”.

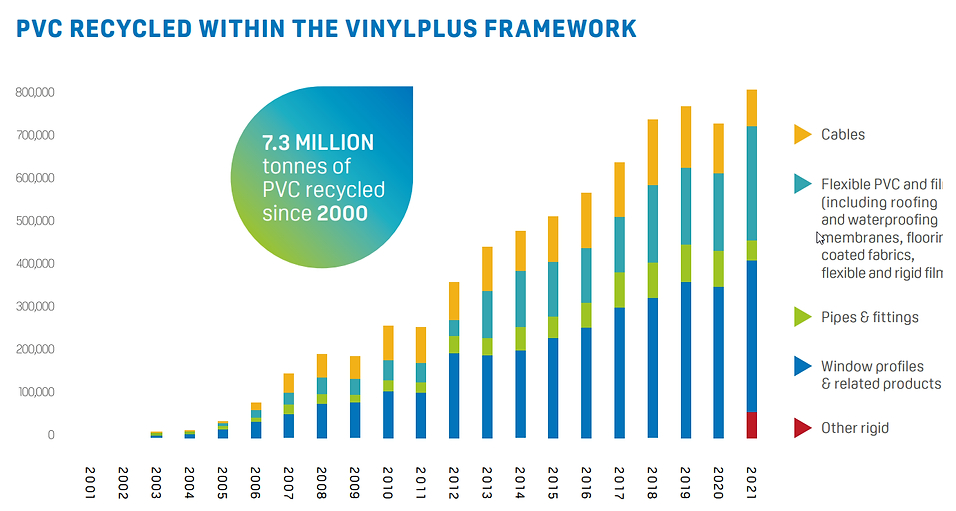

2005 is an important year for CIFRA with the launch of the new economic and responsible axis which is the recycling of PVC. This should enable the company to increase its production and expand its product range, in particular with recycled PVC for retention basins. But 2005 is also the year when CIFRA commits itself to a global responsible approach towards sustainable development.

In 2019, in order to reach a larger number of people and to show its eco-responsible commitment, CIFRA changes its logo and name. Now CIFRA stands for the following acronym: Create, Innovate, Fabricate, Reuse Ad infinium.

2019 also marks the change of the logo determined with the process leaders by questioning the company’s assets and what it wants to do with them locally.

The new logo therefore incorporates an arrow reminiscent of recycling logos and the letters of CIFRA which stood for Calandrage Industriel FRAnçais also stand for Create Innovate Manufacture and Reuse Infinitely! These are the new names of its five letters.

2 – Presentation

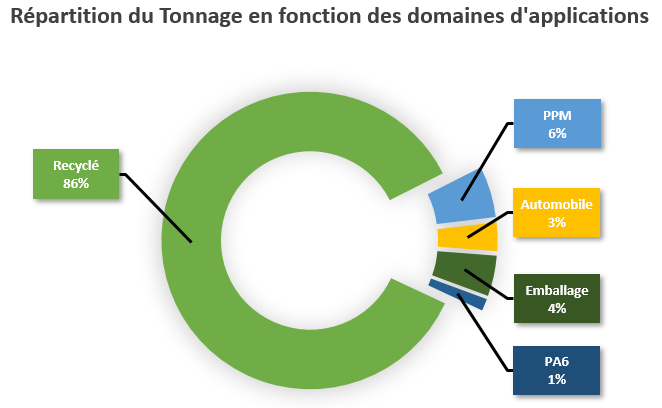

CIFRA, which employs more than 80 people, is currently the leading French producer in the following five markets

– Stationery – Small leather goods (PPM)

– Packaging (food, pharmaceutical, industrial, …)

– Automotive industry

– Printing

– Building industry

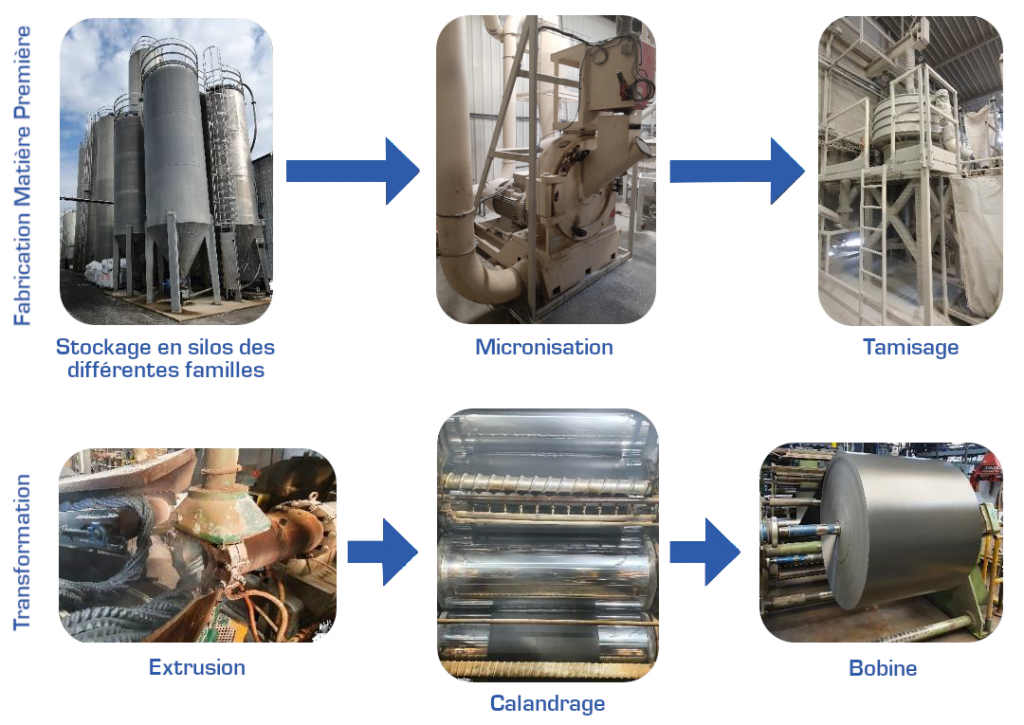

CIFRA produces and manufactures on demand PVC film in different widths or thicknesses:

– Rigid, semi-rigid or flexible

– Crystal, opaque or printed

– Grainy or smooth

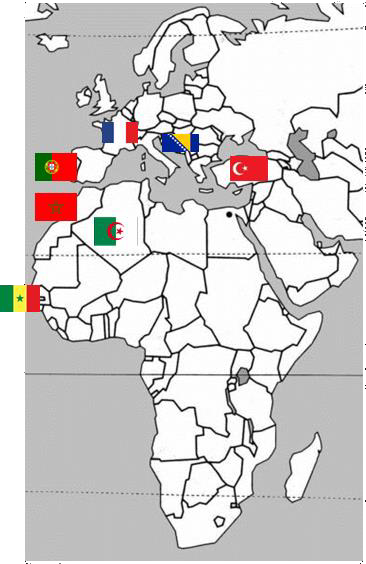

Since 2017, Cifra has created two new companies to collect and micronize PVC at the European level allowing an internal network for the revalorization of waste:

– In Germany, recycling and production of plastic granules Cifra Recycling GmbH works closely with large and small companies in the plastics industry. Our customers can make use of a wide range of raw materials specially designed for their application.

– In the Netherlands, recycling of raw PVC

PVC RECYCLING BV has several production lines to handle, separate, grind, wash and micronize all forms of PVC.

Each company of the CIFRA Group allows us to create our product from A to Z: starting from landfill waste with no added value, which is treated and revalorized and then transformed into PVC films for different fields of application.

CIFRA has been involved in an ISO 9001 certification process since 1998 so that quality management is integrated as a reflex in all stages of marketing, research and development, and especially production.

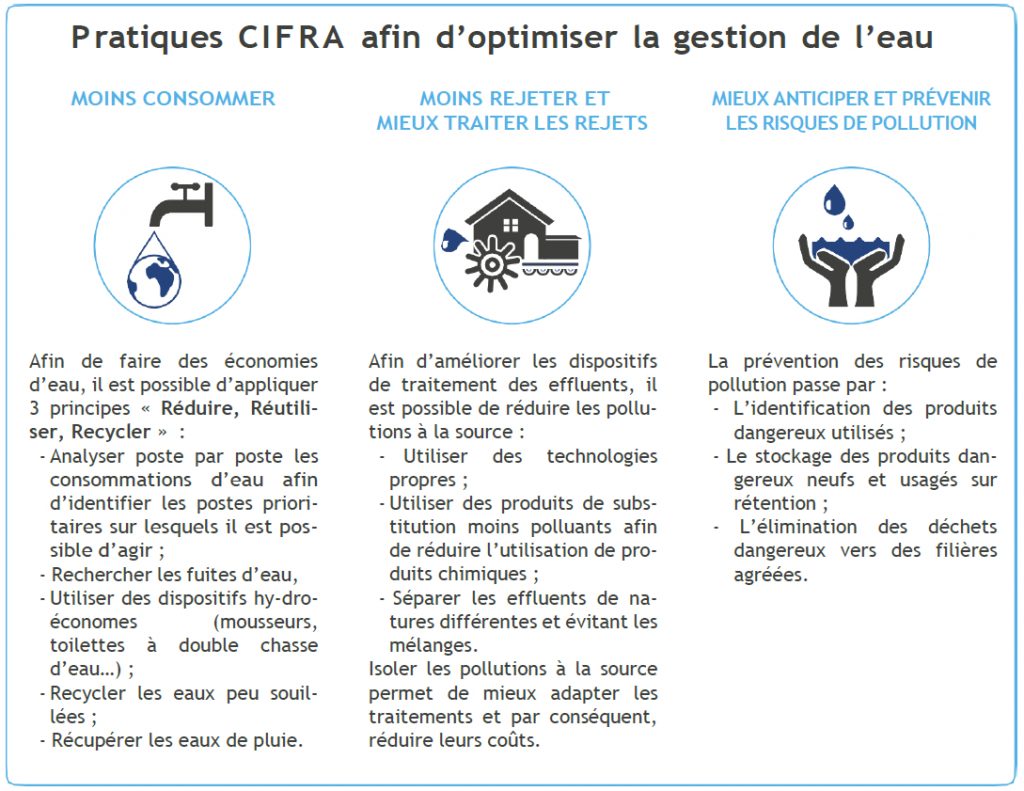

CIFRA is therefore committed to :

– To satisfy its customers, suppliers and partners by providing its services in an environmentally friendly manner

– To ensure that all its installations are in perfect harmony with its natural environment

– To look for new ways of valorization in the framework of the

development of its activities

– To adopt a responsible purchasing policy, by choosing products that are

reusable or recyclable products (according to customer requirements) = eco-design

– To share this environmental awareness by encouraging the staff

to adopt daily gestures respectful of the environment.

Français

Français Español

Español Deutsch

Deutsch